Jonel Hydraulics are New Zealand suppliers of BLOX cribbing, blocking and stabilisation tools made from recycled High Density Polyethylene (HDPE) in Australia. BLOX are made using strict production and quality control processes with known repeatable formula ensuring consistent end product performance and operation characteristics. BLOX are a purpose built tool designed to replace timber blocks that had traditionally been used to stabilise machinery and equipment during repair and maintenance or storage. The pyramid profile on surfaces provides a secure base and top that interlock the blocks at any angle when used in cribbing stacks.

These blocks are ideal in high tonnage load bearing stabilising applications like large structures, bulldozers, scrapers, graders, etc.

Manufactured from repurposed composite plastics that would have normally ended up in landfill, the entire BLOX range is engineered to provide exceptional performance, optimum safety and durability in some of the world’s harshest working environments including, mining, oil and gas, construction and heavy equipment maintenance industries, to name but a few.

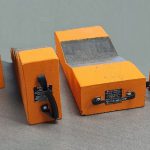

Proudly Australian Made featuring hi-visibility orange finish for trip hazard prevention, sturdy carry handles for reduced pinch points, splinter-free for reduced puncture injuries, non-absorbent and environmentally sustainable. Specifically engineered and designed to replace older, weaker, unreliable and environmentally questionable wooden blocks and dunnage.

Benefits of the BLOX safety support and jacking blocks include:

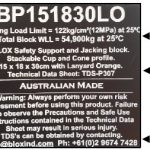

- known working load limits with typical strength ranging from 68.8kg/cm2 to 122kg/cm2 (6.0 to 12.0 MPa) at 25°C

- Composite repurposed plastic construction for optimum durability, fire tolerance, UV resistant and resistance to gas, oil, chemicals and organic substances.

The BLOX are suitable for both active stabilising, where a person is working nearby, and for passive stabilising, where stabilisation is used to keep equipment and material off the ground for storage.

BLOX stabilising supports is an Australian first technology with significant environmental benefits:

- Reduction of waste plastic going into landfill, water systems and stock piles.

- One tonne of discarded plastic waste produces 120 of the BLOX BP122560LO (125 x 250 x 600) stabilising and jacking block.

- For every 1200 BLOX BP122560LO (125 x 250 x 600) stabilising and jacking block produced represents:

- 17m 3 of finished timber not taken (approx. 30 trees)

- 10.8 tonnes of repurposed plastics used

- Unlike wood alternatives, the BLOX range is load rated and warranted for 50 years against splitting, rot, termites and mould.

Warning: Always perform your own risk assessment before using this product. Always know the weight of the equipment or machine being supported. Consult your equipment and machinery manufacturer manual and guidelines for recommended blocking and lifting points. Never exceed the maximum WLL. Under no circumstances does the WLL mentioned above take into consideration point loading or uneven weight distribution of the supported load. `

Technical Data Sheets can be obtained by emailing sa***@jo***.nz or call 0800 JONELS (566 357)

View the reference items at the bottom of the page or get in touch with any questions.

Wedge BX3830LO

Wedge BX101050LO

Wedge BX3830LO

Talk to us about jacks, hydraulic tools and hire

View our range of industrial and hydraulic tooling for hire, email our tool hire team or phone +64 9 274 9294 now to discuss your project requirements.

Custom hydraulic tooling design, manufacture and installation

We can also custom design, manufacture and install a wide range of integrated hydraulic tools and systems for applications such as concrete stressing, drilling, industrial bolting and heavy lifting. Our facilities page shows the scale and range of our hydraulic servicing workshop and our case studies show the range of hydraulic tool design and servicing projects we have done for our clients.

Hydraulic fittings, seals and valves and other hydraulic parts are all part of our tooling range.

Large scale hydraulic repairs and custom design of hydraulic tooling are all part of our day-to-day service. Hydraulic pumps, torque wrenches, jacks and hydraulic stressing tools are in high demand; and if purchasing new hydraulic tools doesn’t suit your business, we offer hydraulic tooling hire services for all types of hydraulic tooling. Our hydraulic servicing includes the supply of hydraulic parts and hydraulic fittings and the workshop team can take care of all your seal and valve requirements to ensure your hydraulic tools are in top form.

Want great advice on hydraulic tooling? Let our knowledge work for you.

Give us a call, we’re always happy to talk about your business. Industrial tooling is a specialist field and it pays to talk to a few experts about any unusual requirements. Go on, pick our brains!